What are the features of industrial oil seals?

The characteristics of industrial oil seal products mainly include the following aspects:

Sealing performance: The main function of the oil seal is to prevent the leakage of liquids or gases, ensuring the normal operation of mechanical equipment, and forming an effective seal on the rotating shaft at high speed to prevent the leakage of lubricating oil or the entry of external contaminants.

Wear resistance and corrosion resistance: The oil seal is usually made of wear-resistant and corrosion-resistant materials, such as nitrile rubber (NBR), fluorine rubber (FPM), and silicone rubber. These materials can still maintain good performance under high-speed rotation or heavy load conditions, extending the service life.

For example, nitrile rubber (NBR) has good heat resistance, wear resistance, and can withstand various lubricating oils, greases, oil-gas mixtures, etc.; fluorine rubber (FPM) is resistant to aging, heat, and oil, and is suitable for almost all lubricating oils, fuels, and gasoline.

Adaptability: The design of the oil seal is flexible and diverse, and can be customized according to different machine types and working conditions to adapt to various complex working environments. For example, silicone rubber oil seals can maintain their rubber sealing material elasticity within the range of -100°C to +300°C for a long time, and have excellent high-temperature performance.

Installation is simple: The installation of the oil seal is relatively simple. It usually only requires attaching it to the shaft or installing it in the sealing groove to complete the installation, thereby reducing installation time and cost.

Thermal resistance: The oil seal will be affected by temperature during operation. Some oil seal materials (such as fluorine rubber and silicone rubber) can maintain good performance at high temperatures.

Chemical resistance: The oil seal usually comes into contact with lubricating oils, liquids, or organic substances, so it needs certain chemical resistance to prevent corrosion or damage from chemical substances. Elasticity and resilience: The sealing lip of the oil seal is usually made of elastic materials, with certain elasticity and resilience, to ensure a close fit with the shaft surface and form an effective seal.

Energy conservation and environmental protection: Effective oil seals can prevent excessive loss of lubricating oil, reduce energy waste, and be beneficial to the environment.

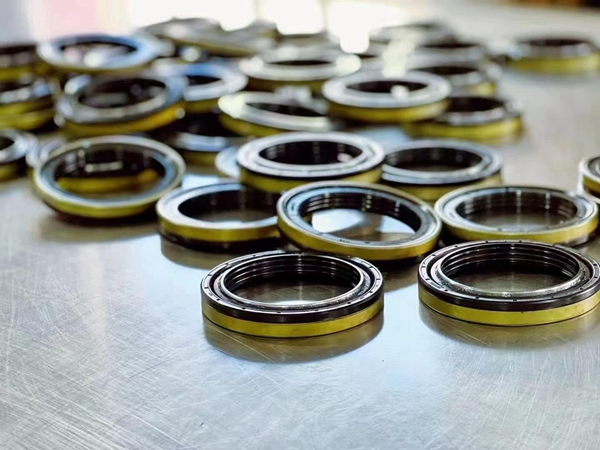

Structural reliability: The outer ring of the oil seal is cylindrical, ensuring the static sealing of the cavity; the rubber outer edge is wrapped around the metal frame, and the sealing lip has a spring to ensure the dynamic and static sealing reliability of the shaft. These features make industrial oil seal products widely used in various mechanical equipment and engineering fields, providing important guarantees for the normal operation and extended service life of equipment.