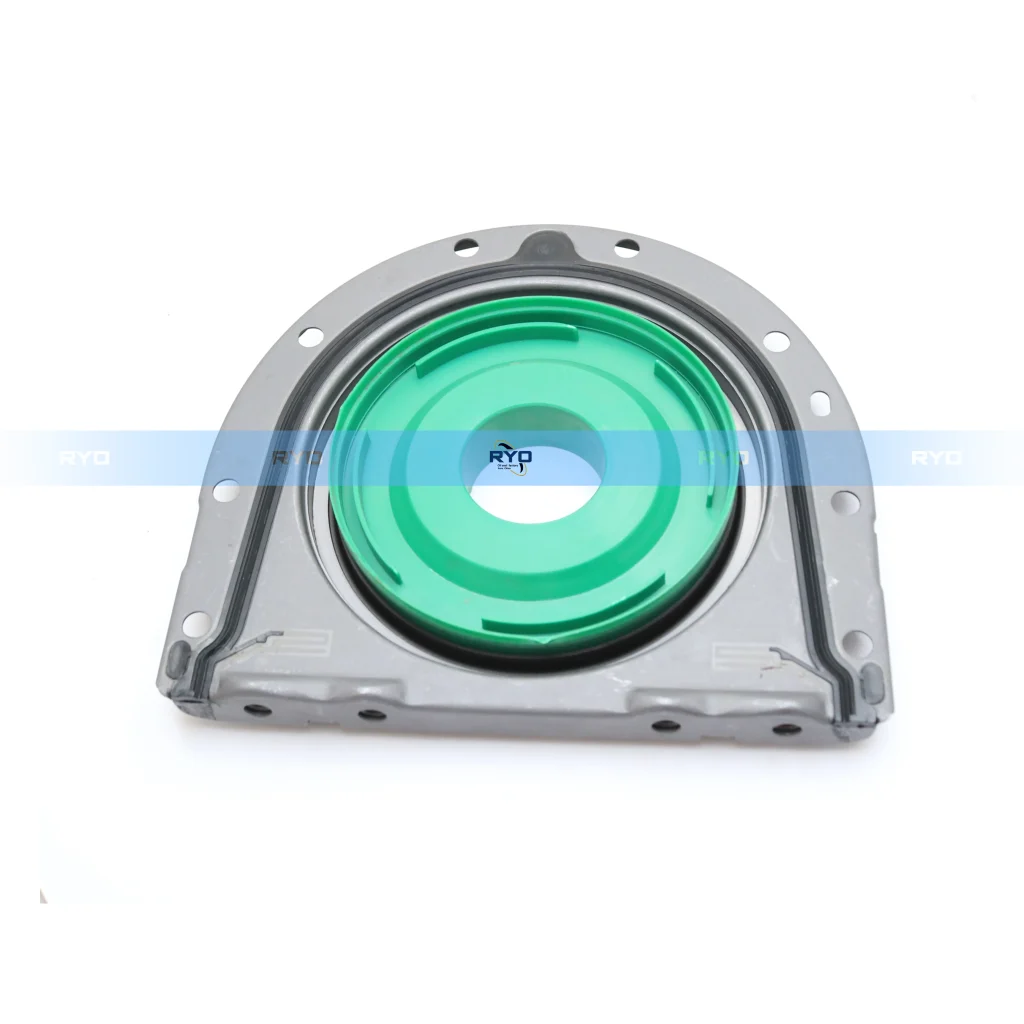

RYO OIL SEAL The modification of the truck engine

Heavy-duty truck oil seals are mainly used in engine crankshafts, transmission input shafts, rear axle hubs, and hydraulic systems, etc. The common characteristics of these areas are high temperature, high speed, and frequent pressure changes. The oil seals must simultaneously possess wear resistance, high-temperature resistance, anti-corrosion properties, and good rebound performance in order to maintain the sealing effect during long-term operation.

The engine and transmission often use fluororubber (FKM) or hydrogenated nitrile butadiene rubber (HNBR), which can withstand high-temperature oils and resist oxidation and aging.

In the case of wheel ends and heavy-load scenarios, it is more advisable to use nitrile rubber (NBR) or polytetrafluoroethylene (PTFE) composite materials, which possess both flexibility and wear resistance characteristics.

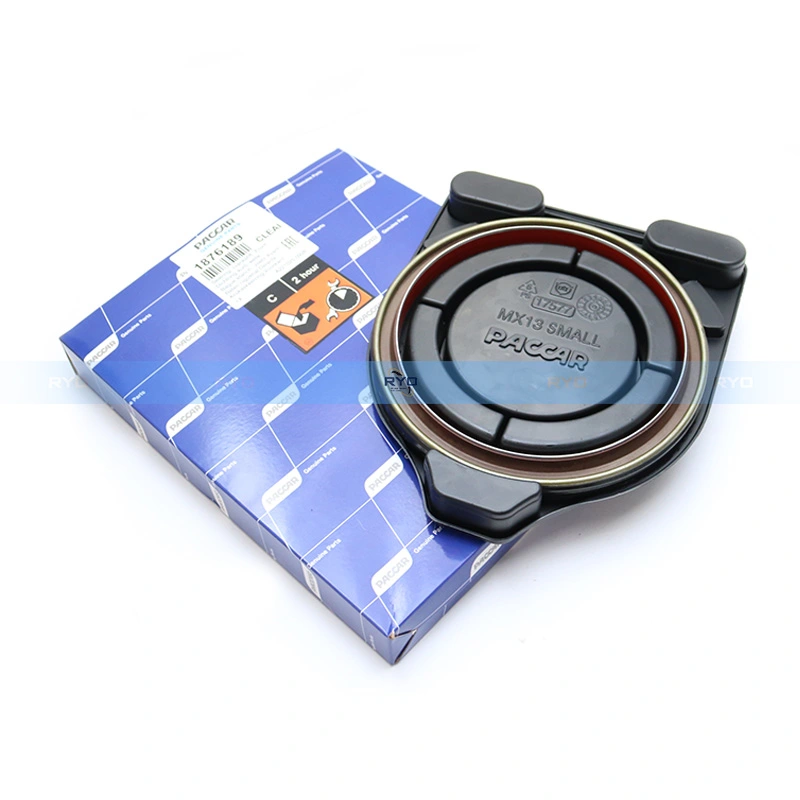

For vehicles operating under more challenging conditions, such as mining trucks or port haulers, some oil seals will adopt a metal frame and double lip design to enhance their support and protection capabilities.

The matching between the sealing lip of the oil seal and the shaft surface is also crucial. If the installation is improper, there is insufficient lubrication, or the roughness of the shaft surface exceeds the standard, it will cause early leakage or erosion of the lip. Therefore, during installation, special tools should be used to ensure the coaxiality of the shaft center, the proper application of oil to the lip, and the flatness of the outer ring during press-fitting, avoiding eccentricity and excessive force.

If you have any oil seal requirements, please contact us.

E-mail:zoe@edenyippgmail-com

WhatsApp / WeChat: 0086 13012129792